The pharmaceutical industry's use of particle analysis software has revolutionised the way that scientists and researchers tackle challenging jobs. This cutting-edge software has become a crucial resource at a time when accuracy, efficiency, and data precision are crucial. It expedites the medication development process and guarantees the quality, safety, and efficacy of pharmaceutical goods by giving pharmaceutical specialists the tools to examine and characterise minute particles. This introduction examines how the dynamic field of pharmaceuticals might use particle analysis software as a driver for innovation, research, and quality control.

Particle Analysis Software: Enhancing Pharmaceutical Research

A specialised computer program called particle analysis software is made to analyse and examine photographs of small objects or particles. It assists scientists and researchers in characterising, measuring, and quantifying particles inside pharmaceutical samples, which is vital for pharmaceutical research. Using particle analysis software can enhance pharmaceutical research in the following ways:

- Particle Size Distribution Analysis:

Because it has an impact on the efficacy and bioavailability of drugs, particle size is a crucial factor in pharmaceutical research. Researchers may better understand how different formulations affect particle size and distribution by using particle analysis software, which accurately quantifies the size distribution of particles inside a sample.

- Quality Control and Assurance:

In the pharmaceutical sector, maintaining product quality is crucial. By detecting anomalies in particle size and form, particle analysis software aids in quality control and helps ensure that manufactured goods satisfy high requirements.

- Drug formulation:

To obtain desirable drug release patterns, researchers employ particle analysis tools to optimise the particle size, shape, and dispersion. This aids in the creation of potent and effective medication compositions.

- Enhancing bioavailability:

Drug development might be difficult for medications that are poorly soluble in water. By modifying particle properties, particle analysis software aids in the study and improvement of medication solubility, eventually increasing the medicine's bioavailability.

- Testing for Stability:

Pharmaceutical items need to remain stable throughout their shelf life. Software for particle analysis tracks alterations in particle size and distribution over time to help forecast product stability and storage conditions.

- Inhalable drugs:

To determine the size and distribution of particles that can be absorbed into the respiratory system, detailed particle analysis is essential for inhalable medication products. The effectiveness and safety of inhalable drugs are guaranteed by this information.

- Regulatory Compliance:

The integrity and security of electronic records in pharmaceutical research and production may be ensured by 21 CFR Part 11 compliance, which can be met using particle analysis software.

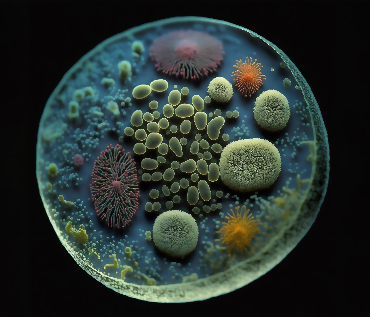

- Image-driven Research:

To comprehend the characteristics of particles, many pharmaceutical research initiatives rely on in-depth picture analysis. Scientists may extract useful information from photos using particle analysis software, enabling study of particle shape, aggregation, and other topics.

- Customizable Solutions:

Particle analysis software offers data analysis and insights that are adaptable to particular research demands and applications in the pharmaceutical business.

In conclusion, particle analysis software is a crucial tool in pharmaceutical research since it enables scientists and researchers to understand crucial aspects of particle properties. It finally aids in the production of safe and effective pharmaceutical goods by increasing the effectiveness of research and development procedures, guaranteeing product quality and regulatory compliance, and so forth.

How Does Particle Analysis Software Play a Pivotal Role in Developing Inhalable Medications?

To create inhalable pharmaceuticals that are both effective and safe for patients, it is crucial to use particle analysis tools during the development process. Here are some significant uses of particle analysis software for inhalable drugs:

- Particle Sizing and Distribution:

Powders or small particles are frequently seen in inhalable drugs. Researchers and producers may make sure that the medication's particle size falls within the necessary range for efficient pulmonary administration by using particle analysis tools to precisely evaluate the size and distribution of these particles.

- APSD Analysis:

To effectively reach and deposit in the respiratory system, inhalable drugs need to have a certain aerodynamic size distribution (APSD analysis). The APSD may be calculated using particle analysis tools, guaranteeing that the medication's particles are appropriate for inhalation and efficient transport to the lungs.

- Analysing Formulations:

Particle analysis software is used by manufacturers to analyse the formulations of inhalable medications for quality. To maintain consistency in product quality and performance, it aids in identifying any differences in particle size and distribution.

- Device Optimisation:

Metered-dose inhalers (MDIs) or dry powder inhalers (DPIs) may both have their performance evaluated using particle analysis software. Researchers can improve the design of these devices for more effective medicine administration by analysing the particles that are released by them.

- Respiratory Safety Assessment:

It is essential for safety assessment to comprehend the size and distribution of particles that can enter the respiratory system. Software for particle analysis helps to find particles that might be harmful to lung health.

- Testing for Stability:

Over time, inhalable drugs must keep their particle properties. During stability testing, particle analysis software helps monitor changes in particle size and distribution to make sure the drug keeps working as intended for the duration of its shelf life.

- Particle Size Characterization:

Pharmaceutical researchers utilise particle analysis tools to examine how various formulations and production procedures affect particle characteristics. This makes it possible to create novel inhalable drugs with enhanced effectiveness and safety characteristics.

- Regulatory Compliance:

For inhalable drugs, regulatory bodies frequently request information on particle size and dispersion. Particle analysis software can produce the data required for regulatory filings, assisting businesses in complying with regulations.

- Clinical research:

By giving information on the particles inhaled by patients, particle analysis can help clinical research. This information is essential for determining how well the drug works in actual clinical settings.

In conclusion, particle analysis software is an essential instrument in the creation, monitoring, and evaluation of the safety of inhalable drugs. It guarantees that the formulation, production, and administration of these pharmaceuticals optimise therapeutic effects while reducing any possible dangers to the respiratory system.

How Does Particle Analysis Software Aid Image-Driven Research in the Pharmaceutical Sector?

Particle analysis software offers sophisticated tools and skills for analysing and extracting useful information from photos, which greatly helps image-driven research in the pharmaceutical business. Here is how image-driven research in this subject is supported by particle analysis software:

- Particle identification and classification:

Pharmaceutical researchers frequently work with complicated combinations of particles in their samples. Active pharmaceutical ingredients (APIs), excipients, contaminants, and impurities are just a few examples of the various sorts of particles that particle analysis software can automatically recognise and categorise. Characterising and measuring distinct components in a sample is made easier thanks to this.

- Analysis of Particle Size and Shape:

The formulation and effectiveness of drugs are greatly influenced by the size and shape of the particles. Researchers may better understand how many variables affect particle qualities by using particle analysis software, which can measure and analyse these metrics with accuracy. For optimising medicine compositions, this knowledge is crucial.

- Aggregation Analysis:

Particle aggregation must be understood since it affects the stability and effectiveness of a product. The detection and measurement of particle aggregation using particle analysis software can shed light on potential formulation problems and help researchers make the required corrections.

- Morphological Studies:

Thorough morphological research of particles can provide important details regarding their physical properties. Researchers can use particle analysis software to analyse particle morphology, which includes elements like crystallinity, surface roughness, and porosity.

- Image improvement and Preprocessing:

Particle analysis software frequently comes with capabilities for image improvement and preprocessing to increase the accuracy of analysis. This can aid researchers in denoising pictures, boosting contrast, and eradicating background noise.

- High-Throughput Analysis:

Particle analysis software provides automation and batch processing capabilities for research projects requiring a lot of photos. High-throughput analysis is made possible, which helps researchers save a lot of time and effort.

- Data Analysis:

Particle analysis software often offers capabilities for efficiently visualising and presenting data. To accurately express their results and thoughts, researchers might create graphs, charts, and reports.

- Customised Analysis Parameters:

Depending on the study project, certain analysis parameters may be needed. To suit the specific requirements of their investigations, particle analysis software frequently enables researchers to modify settings and criteria.

- Quality Control:

Particle analysis software is a tool that may be used for quality control in the pharmaceutical manufacturing industry. It helps make sure that product particle properties are constant and fulfil predetermined requirements.

- Regulatory Compliance:

A lot of pharmaceutical research initiatives need to abide by regulatory norms and requirements. For regulatory filings, particle analysis software can assist in producing data and reports that are compliant.

In conclusion, particle analysis software is a crucial tool for image-driven research since it enables pharmaceutical researchers to accurately and precisely extract information from photographs. It advances knowledge of particle characteristics, aids in medication formulation and development, promotes quality assurance, and helps the pharmaceutical sector comply with regulatory standards.

How Breakthroughs in Nanomedicine are Aided by Particle Analysis Software

The advancement of nanomedicine, a subject that focuses on using nanoparticles and nanotechnology for medicinal applications, is greatly aided by particle analysis software. Here are several ways that particle analysis software advances nanomedicine:

- Precise Nanoparticle Characterization:

The foundation of many nanomedicine applications, including medication delivery systems and imaging agents, is the nanoparticle. The size, shape, and distribution of nanoparticles are precisely characterised using particle analysis software, guaranteeing that they satisfy the conditions necessary for their intended purpose.

- Optimising Drug Delivery Systems:

Drugs are packaged and delivered to specific locations in the body using nanoparticles. Particle size, surface charge, and drug loading capacity are some of the variables that particle analysis software examines to assist researchers in optimising these drug delivery systems. This optimisation improves the effectiveness of medicine delivery while lowering negative effects.

- Illness Diagnosis:

MRIs, CT scans, and fluorescence imaging all use nanoparticles as contrast agents, which are enhanced imaging agents. The right size and characteristics of these nanoparticles are guaranteed by particle analysis software, enabling early illness diagnosis and more precise diagnostics.

- Nanoparticle Characterization:

Testing for stability at the nanoscale is important because nanomedicine products may face particular difficulties because of their small size and intricate formulations. To create stable and long-lasting nanomedicines, particle analysis software tracks changes in nanoparticle characteristics over time.

- Customised Nanoparticle Design:

To create nanoparticles with precise properties for particular medicinal uses, researchers might employ particle analysis tools. They can produce nanocarriers that are tailored for drug release profiles and targeting abilities by modifying particle size, shape, and surface features.

- Safety evaluation:

In nanomedicine, safety is of utmost importance. Particle analysis software examines how nanoparticles interact with biological systems, such as cell absorption and dispersion within tissues, to determine their potential toxicity.

- Disease-Specific Nanoparticles:

Nanomedicine enables the creation of medicines tailored to certain diseases. Designing nanoparticles that may specifically target sick cells or tissues while sparing healthy ones with the use of particle analysis tools helps to minimise collateral harm.

- Biocompatibility of Nanoparticles:

Understanding how nanoparticles interact with biological systems is essential for determining their biological compatibility. To ensure that nanoparticles do not cause adverse reactions or immunological responses, researchers analyse the biocompatibility of nanoparticles with the aid of particle analysis tools.

- High-Throughput Screening:

Particle analysis software provides automated and high-throughput analytical capabilities for large-scale screening of nanoparticle libraries, expediting the identification of new candidates for nanomedicine.

- Regulatory Compliance:

To ensure that nanomedicine products fulfil safety and effectiveness criteria, and regulatory clearances in the pharmaceutical and medical device industries, particle analysis software might be crucial.

In conclusion, software for particle analysis is a crucial tool for promoting advances in nanomedicine. It makes it possible to precisely characterise, optimise, and customise nanoparticles for a variety of medical applications, which in turn paves the way for the creation of safer and more efficient nanomedicine solutions for disease detection, treatment, and prevention.

Varieties of Particle Analysis Software Employed in the Pharmaceutical Sector

Various particle analysis software programs are used by the pharmaceutical sector to suit its unique requirements in the stages of research, development, quality control, and manufacture. Some of the well-known particle analysis software programs used in the pharmaceutical industry include the following:

- ImageJ: ImageJ is a popular open-source tool for image processing and analysis in the pharmaceutical sector. For particle size and shape analysis, it provides a variety of plugins and tools.

- Image-Pro Plus: Image-Pro Plus is an extremely functional image analysis program that offers capabilities for particle counting, size measurement, form analysis, and other tasks. It is employed in pharmaceutical quality assurance and research.

- Morphologi G3: The Morphologi G3 is an automated image analysis system created especially for characterising particles, such as their size, shape, and number. Pharmaceutical powder analysis is one of its uses.

- Mastersizer: The Mastersizer series from Malvern Panalytical is a collection of devices that includes software for particle size analysis using laser diffraction. Drug formulation development frequently makes use of it.

- Zetasizer software: This software is used to quantify particle size, zeta potential, and molecular weight of particles and molecules in pharmaceutical applications. It is frequently used in conjunction with Malvern Panalytical's Zetasizer devices.

- LabVIEW: A versatile software platform for customising particle analysis solutions and combining them with other lab apparatuses, LabVIEW is utilised in pharmaceutical research.

- FlowCam: An imaging-based particle analysis device with specialised software, called FlowCam, can analyse particles in fluids, including pharmaceutical samples. Particle size, shape, and concentration may all be instantly analysed.

- Particle size analyzers from Horiba Partica: Horiba provides a range of particle size analyzers with related software for pharmaceutical applications, such as quality control and research.

- Particle Insight: A method for image analysis developed by Micromeritics, is used to assess the size and form of particles in medicinal ingredients. Numerous medicinal uses are appropriate for it.

- ImageProVision Technology: Provides several particle analysis software options, such as ipvClass, ipvPSA, and ipvMicrobe, that are designed for pharmaceutical research and quality control.

Their client-centred strategy guarantees cutting-edge solutions that address the unique requirements of pharmaceutical clients. ImageProVision's several applications offer high-performance image processing and analysis, whether it's automating particle categorization, guaranteeing compliance with 21 CFR Part 11, or optimising particle counts. Discover how ImageProVision's technology may improve your pharmaceutical research, quality control, and production operations by visiting their website right away.

Conclusion

In conclusion, particle analysis software is a game-changing instrument for the pharmaceutical sector that greatly streamlines and improves the research procedure. Drug development is sped up, product quality is ensured, and regulatory compliance is made easier because of the accurate data on particle size, shape, and dispersion provided.

Particle analysis software simplifies research while also assisting in the development of safer, more effective pharmaceutical goods in the pursuit of treatments and pharmaceuticals that work better. Its capacity to provide scientists and researchers with in-depth knowledge of particle characteristics emphasises the crucial role it will play in influencing pharmaceutical innovation and improving healthcare for all people.