The Science

Behind Every Pixel

The IPV Difference

Products in our technology suite

Clients across sectors

Installations successfully completed

ImageProVision

As pioneers in advanced image processing, we redefine how industries interpret the microscopic world, turning the unseen into undeniable clarity. Our innovations empower pharmaceutical leaders, scientific researchers, and industrial giants to extract definitive insights from complex visual data, accelerating discovery, meeting compliance & enhancing quality control.

Meet CLAIRITY Assist

Have a question about our products, Company or applications?

Our chatbot gives you instant answers, guides you to the right product, and helps you explore solutions tailored to your lab needs.

CLAIRITY™

Suite

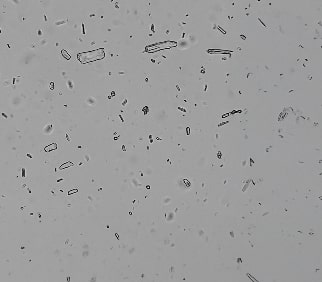

PARTICLE

Particle size and shape analysis.

CLAIRITY™ PARTICLE is a high-performance software solution for particle size analysis, shape profiling…

Read More

CLAIRITY™

Suite

AUTO

Automated microscopy tools.

CLAIRITY™ AUTO is an advanced, automation-first solution for intelligent particulate matter detection…

Read More

CLAIRITY™

Suite

NANO

Nano-scale analysis.

CLAIRITY™ NANO is a precision-focused software platform for nanoparticle analysis…

Read More

CLAIRITY™

Suite

THERMAL

Correlation with thermal behaviour.

CLAIRITY™ THERMAL is a high-precision microscope image analysis software that merges…

Read More

CLAIRITY™

Suite

SEAM

Seam Analysis.

CLAIRITY™ SEAM delivers advanced seam analysis for pharmaceutical and nutraceutical capsule inspections…

Read More

CLAIRITY™

Suite

VIA

Vial Inspection analysis.

In pharmaceutical manufacturing, visual defects such as particulate matter inside sealed…

Read More

CLAIRITY™

Suite

SIA

Static Image analysis.

Particle characterization plays a foundational role in developing and manufacturing pharmaceutical products…

Read More

CLAIRITY™

Suite

MORPHOWIZ

AI-based particle analysis.

CLAIRITY™ MORPHOWIZ is an AI/ML-powered platform for particle detection, classification…

Read More

CLAIRITY™

Suite

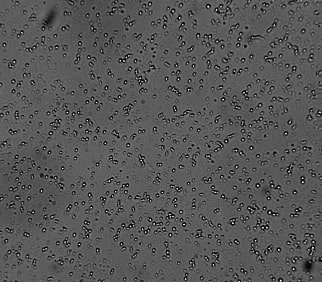

XCELL

Cell Analysis.

CLAIRITY™ XCELL is an advanced cell analysis software designed for automated…

Read More

CLAIRITY™

Suite

MICROBE

Microbial analysis and colony counting.

CLAIRITY™ MICROBE is an AI-powered solution for counting bacterial colonies across various microbiological workflows—from CFU…

Read More

CLAIRITY™

Suite

PROOFCHECK

Smart proof-reading system.

CLAIRITY™ PROOFCHECK (ipvProofCheck) is a high-precision proofreading software for…

Read MoreLegacy Prodcuts

Pioneering Solutions that Defined the Category

Image ProVision Technologies specializes in advanced imaging systems that empower pharmaceutical, biotech, and industrial labs with accurate, automated, and compliant analysis tools. Our product portfolio supports a wide range of applications—from particle size analysis to microbial counting and packaging quality checks.

Explore Legacy LinesApplications

Precision imaging across critical applications

Our Services

Field-tested help for

lab-critical tasks

Academia

Bombay College of Pharmacy (Mumbai)

Indira College of Pharmacy (Pune)

Poona College of Pharmacy (Pune)

Dr. D.Y. Patil Vidyapeeth (Pune)

Bharati Vidyapeeth Pharmacy College (Navi Mumbai)

Institute of Chemical Technology (ICT, Mumbai)

IIT-BHU (Varanasi)

Dr. Bhanuben Nanavati College of Pharmacy (Mumbai)

Our clients

We work with some of the leading pharmaceutical and biotech companies across research, manufacturing, and quality assurance.

View AllIndustries

Serving domains that depend on clarity