Table of content

2. What is Particle Size Analysis?

3. Why Is Particle Size Analysis Important?

4. Determination of Particle Size By Microscope

5. What are the other techniques of Particle Size Analysis?

Introduction

In this article, we are going to talk about Particle Size Analysis, which is a complicated process and includes sampling, dispersion, and accurate utilization of tools & equipment. Because any one of these undertakings can be inadequately conducted, reference substances have been created in the past few years. These are differentiated by measuring the size distribution very cautiously by several expert laboratories. The reference substances have a certified size distribution with error bands and can be utilized to examine the techniques utilized to attain the size distribution.

What is Particle Size Analysis?

Particle size analysis is utilized to determine the size distribution of particles in a provided sample material. Particle size analysis can pertain to solid substances, emulsions, suspensions, and aerosols. To measure the particle size, so many different methods are employed.

Some particle sizing techniques can be utilized for a broad range of specimens, but some of them can only be utilized for certain applications. It is quite significant to choose the most favorable technique for different types of sample materials because different techniques can generate relatively different outcomes for a similar sample substance.

Particle size analysis is used in various industries. Particle size analysis is a very crucial test and is utilized for quality control in several distinct industries. In just about every business where milling or grinding is utilized, particle size is a crucial factor in specifying the productivity of manufacturing procedures and execution of the final products. Some of the businesses and product categories where particle sizing is utilized include pharmaceuticals, building elements, paints and coatings, food & beverages, and aerosols.

Why Is Particle Size Analysis Important?

As particle size analysis plays a vital role in the execution of the final product, you must implement particle analysis in your quality control protocol. Not understanding the size of the individual particles of the material can result in major problems within your production line and can cost you thousands of rupees, if not millions of dollars in possible earnings.

For instance, in the fracking industry, if you are operating with a mixture of particle sizes that are different from each other, then an unequal distribution of vacuum pressure can be developed. In turn, the fracture in which the oil is being brought out may change positions, shutting the wellbore and hampering the generation of oil.

On the other hand, the pharmaceutical industry completely depends on the six particles as it regulates the rate at which medicine crumbles and disperses throughout the body. A failure to understand and control the size of the particle of any given medicine can eventually result in expensive lawsuits and, most importantly, it can cause damage to the patient putting up with the medication.

In simple terms, understanding & knowing the size of the particle is just one of the many precautions required to assure the quality, specification, and productiveness of the product.

Determination of Particle Size By Microscope

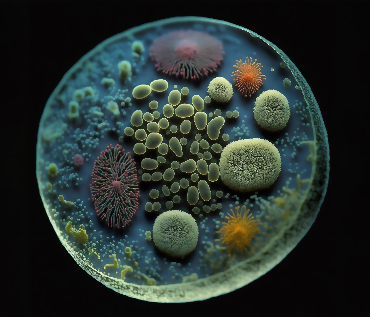

Here, microscopy can be utilized as an absolute technique of particle size analysis, as it is the only technique in which individual mineral particles can be observed and measured. The image of a particle observed in a microscope is two-dimensional, and from this image, the size of the particle can be estimated.

Microscopic sizing encompasses a comparison between the projected area of a particle and the regions of reference circles, or graticules, of the already known sizes. Hence, it is important for significant results that the mean projected regions of the particles are representative of the size of the particle. This needs a random exposure in all three dimensions of the particle on the microscope slide, which is uncertain in most circumstances.

The optical microscope technique applies to particles that fall in the size range of 0.8–150 µm and down to 0.001 µm utilizing electron microscopy.

Practically, all microscopy techniques are achieved on exceptionally small laboratory samples, which must be accumulated with enormous amounts of care to be representative of the procedure stream under study.

Also, in physical optical microscopy, the particles that are dispersed are viewed by transmission, and the regions of the magnified pictures are distinguished from the regions of circles of well-known sizes inscribed on a graticule.

The comparative numbers of particles are specified in each of a series of size grades. They all exemplify the size distribution by a number from which it is apparent to evaluate the distribution by volume and if all the particles have the same consistency & thickness, the distribution by weight.

Manual examination of microscope slides is dreary and can be error-prone. Semi-automatic and automatic systems have been formulated that help speed up the examination process and decrease the tedium of manual techniques.

What are the other techniques of Particle Size Analysis?

Here are some of the techniques:

1. Particle Sizing By Laser Diffraction

In recent times, laser diffraction has become one of the most commonly utilized particle sizing methods, primarily for particles falling in the range of 0.5 to 1000 microns. It operates on the principle that when a beam of light (a laser) is dispersed by a group of particles, the angle of light scattering is inversely proportional to the size of the particle, which means the tinier the size of the particle, the larger the angle of light scattering.

Particle Sizing by Laser diffraction has evolved and become way too popular because it can pertain to many distinct sample categories, which include suspensions, emulsions, dry powders, and even aerosols. It is also a very quick, credible, and reproducible method that can truly measure over a very broad range of sizes.

2. Dynamic Light Scattering

Dynamic light scattering, also known as DLS, is a non-invasive and sensitive method to calculate the size of particles in suspension and molecules that are smaller than a micron in a solution. At the time of DLS, a laser is shot with the help of a polarizer & into a sample material, and the light is scattered in every direction.

This scattered light reaches another polarizer, where it is obtained by a photomultiplier, and then the resulting image is displayed on a big screen; this is known as a speckle pattern. This procedure is enacted again & again, and the set of speckle patterns generated are evaluated by an auto-correlator that correlates the intensity of the light of each spot over time. After that, Fluctuating mathematical approaches are utilized to determine the auto-correlation information.

3. Acoustic Spectroscopy

Acoustic Spectroscopy utilizes ultrasound to obtain data on the particles dispersed in a fluid. Then the dispersed particles absorb and scatter sound waves, identical to the light. This method scales the ultrasound frequency vs attenuation coefficient. This gives raw data that can be utilized to evaluate the particle size distribution of any component that is in a fluid system.

Conclusion

In conclusion, there are many distinct particle size analysis methods, and the nature of the particle specifies which technique is to be utilized. Each method has a history of interpreting its beliefs, and they all have developed to become more efficient with time. With more study into the particle size analysis methods, methods to expand and their benefits will become accessible to all very soon.